Different requirements for the usage of the clean room facility combined the working conditions, there are different selections of the Air Conditions Handling system for different users.

·Combined air treatment unit + Chiller + High Efficient air supply

This is the most traditional design of purifying air conditioning system. The combined air treatment unit contains various functional sections, such as mixing section, primary filter section, surface cooling section, secondary return air section (or intermediate section), heating section, humidification section, medium effect filter section, fan section, etc. The cold source is provided by the chiller.

·Water cooler + Booster Air Cabinet + High Efficient air supply

Compared with the first scheme, this is a relatively simple air conditioning scheme. It can greatly reduce the area of the machine room, the water cooler can be arranged in the smaller machine room or the purification workshop according to the specific situation, and the pressurized air cabinet can also be arranged in the machine room or suspended in the machine room or in the interlayer.

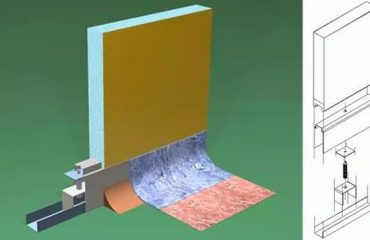

·Split air-conditioning cabinet + FFU sir supply

This is the simplest air conditioning scheme. A split air conditioning cabinet machine is arranged directly in the workshop, surrounded by colored steel, and then opened on the color steel plate at the return tuyere of the cabinet machine (with primary effect filter net), and the FFU is evenly arranged on the ceiling. This scheme is suitable for dust-free workshop with low precision of indoor temperature and humidity.