Clean room, generally in the appearance can judge the quality of the project, small details have little impact on the overall quality of the project, and easy to remedy. Purification works are different, from the beginning of the design, to raw materials procurement, equipment installation, specific construction, any link is not allowed a little problem. A little carelessness, a small error, will lead to failure to meet the design requirements. Careful design, careful construction, careful preparation, high-quality materials, high-quality equipment, is a necessary condition for qualified purification clean room.

In accordance with the business objectives and production programme of the enterprise, the space required for personnel, equipment and materials shall be allocated in the most appropriate manner and in the most efficient manner in order to maximize the economic benefits of production, in accordance with the entire process of receiving, manufacturing, packaging and shipping documents from the raw materials.

A standard clean room facility should be achieved as below:

Efficient production and operation,

Reasonable and effective process realization mode,

Smart Architecture and Space Design,

Green utility design.

General, a standard clean room workshop decoration construction projects include:

1. Dust-free purification Clean room production mainly includes air conditioning system, ceiling, floor, partition, and lighting.

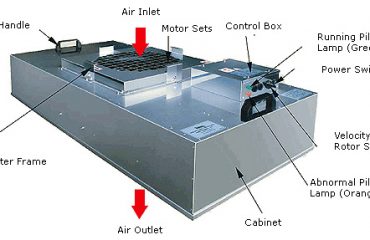

2. Air conditioning system: including air duct, filter system, mainframe, FFU, etc.

3. Ceiling: including the outline beam, suspenders, ceiling lattice beam, the material is generally: color plate and dustless plate.

4. Floor: Epoxy floor or PVC floor.

5. Partition wall: including doors and windows, the material is colored steel plate, but there are many kinds of sandwich core of colored steel plate.

6. Lighting appliances: use dust-free special lamps.