Clean room brief introduction for semiconductor industry

Tuesday, 03 August 2021

Clean room where the air suspended particle concentration is controlled. Its construction and use should reduce indoor entrapment and produce stranded particles. Other relevant parameters of indoor installation requirements such as temperature, humidity and pressure shall be controlled. How the dust is produced in a clean room. ●Personnel factors ●Production process production ●Equipment operation generated

A Brief introduction of a clean room test report

Monday, 26 July 2021

In order to make sure that the clean room was well meet the design requirements, before deliver the clean room project to user, construction unit should be arrange test the whole system, including below: ●Detection of the cleanliness for a clean room facility. The biological clean room shall be tested for floating bacteria and settlement

Difference between dust-free clean room and purifying clean room

Monday, 12 July 2021

The biggest difference between the dust-free clean room and the purifying clean room is the different industry they used. Dust-free clean room are widely used in high-tech fields such as electronics, aerospace, bioengineering pharmaceutical, precision machinery, chemical industry, food, mechanical manufacturing and modern science. Purifying clean room is mainly reflected in the laboratory, food workshop,

Biosafety Laboratory

Monday, 05 July 2021

The main control objects of biological laboratory are microorganisms, bacteria and other living particles. It’s a growing, reproducing particle. The pollution it produces is not just the microbes themselves. And there’s the secondary pollution from their metabolism. Strict measures should be taken in the production process of related products to prevent the products from being

Four technical elements for a modular clean room project

Tuesday, 29 June 2021

From a manufacturer who build up the clean room facility, who will use the clean room facility and who will take charge the maintenance of the clean room facility. The purification system of the clean room shall have at least the initial, medium and HEPA system at the end section. Air supply of the clean

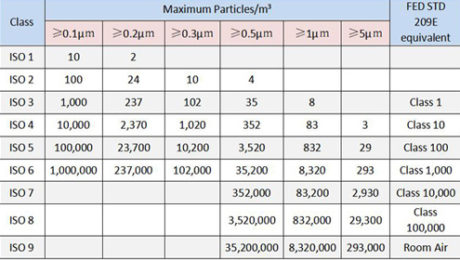

Significance for the clean room classification

Wednesday, 23 June 2021

ISO 3/CLASS 1 Microelectronics industry, mainly used for manufacturing integrated circuits, whose precision of submicron. ISO 4/CLASS 10 Mainly used in the semiconductor industry with a bandwidth of less than 2 microns. ISO 5/CLASS 100 Sterile manufacturing process mainly used in the pharmaceutical industry; Surgery, including the implantation procedure; Integrated circuit manufacturing; Isolation and treatment

Elements of control the customized modular clean room system

Friday, 18 June 2021

●Cleanliness ●Temperature and Humidity ●Pressure difference ●Air flow organization ●Illuminance ●Self cleanliness Technical for a standard clean room facility 1.The air supply should be at least 3 different filters: primary, medium, and HEPA. And the HEPA should be set at the end of the system. 2.The clean room shall have sufficient purification and air conditioning

Main pollution for a standard clean room

Wednesday, 09 June 2021

The greatest threat to clean room pollution comes from the user itself. Microbial control in the medical and pharmaceutical industries is very important, especially those that may be deposited from shedding skin into the airflow. The study of the clean room microflora is important for the microbiologist and quality control personnel to evaluate the change

GMP clean room for pharmaceutical industry

Wednesday, 02 June 2021

In the medicinal sense, the clean room is the GMP sterile specification clean room. Clean laboratories, due to the strict requirements of manufacturing technology upgrading, are also known as the “guardian of high – end manufacturing”. Clean room is designed to maintain extremely low levels of particles such as dust, organisms in the air, or