Main technical parameters of the clean room for GMP pharmaceutical plant

Tuesday, 19 October 2021

●Indoor air changes: Class 100,000 10-15 times/hour; Class 10,000 15-25 times/hour; Class 1,000 50-52 times/hour; ●Average wind speed of Class 100 operating point section 0.25-0.35m/s. Indoor noise: ≤ 65dB (A); ●Indoor pressure difference: high clean room area for adjacent low clean room area ≥ 5Pa, to non-clean room area ≥ 10Pa; ●Indoor temperature: Winter :16℃±

The microbiology laboratory of the clean room

Wednesday, 25 August 2021

The basic idea of laboratory design is economical and practical. The purification requirement level is class 10000. The laboratory design has preparations for experiments such as greater, secondary, wind shower and buffer. The principle of separating flow and logistics is adopted to reduce experimental pollution and ensure safety. The layout is compact and reasonable, meeting

There are 4 different air supply and air return plans for a clean room project

Monday, 16 August 2021

Here are the advantages and disadvantages for the different plans for a general clean room working area. ●Air supply and air return all from the ceiling Suitable for the class standard: ISO7, ISO8 Advantages: Simple and low cost Disadvantages: Poor airflow resistance is difficult to effectively control dust ●Air supply from the ceiling & air

How to classification the different class standard to a clean room facility in pharmaceutical industry

Wednesday, 11 August 2021

Generally, there are 4 class standard for the production of sterile drugs in a pharmaceutical facility. ●ISO 5/ Class 100: High risk operating areas such as filling areas, areas where rubber plugs are placed and open packaging containers in direct contact with sterile preparations and areas where sterile assembly or connection operations shall have the

Clean room brief introduction for semiconductor industry

Tuesday, 03 August 2021

Clean room where the air suspended particle concentration is controlled. Its construction and use should reduce indoor entrapment and produce stranded particles. Other relevant parameters of indoor installation requirements such as temperature, humidity and pressure shall be controlled. How the dust is produced in a clean room. ●Personnel factors ●Production process production ●Equipment operation generated

A Brief introduction of a clean room test report

Monday, 26 July 2021

In order to make sure that the clean room was well meet the design requirements, before deliver the clean room project to user, construction unit should be arrange test the whole system, including below: ●Detection of the cleanliness for a clean room facility. The biological clean room shall be tested for floating bacteria and settlement

Four technical elements for a modular clean room project

Tuesday, 29 June 2021

From a manufacturer who build up the clean room facility, who will use the clean room facility and who will take charge the maintenance of the clean room facility. The purification system of the clean room shall have at least the initial, medium and HEPA system at the end section. Air supply of the clean

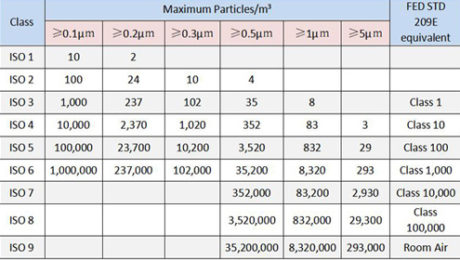

Significance for the clean room classification

Wednesday, 23 June 2021

ISO 3/CLASS 1 Microelectronics industry, mainly used for manufacturing integrated circuits, whose precision of submicron. ISO 4/CLASS 10 Mainly used in the semiconductor industry with a bandwidth of less than 2 microns. ISO 5/CLASS 100 Sterile manufacturing process mainly used in the pharmaceutical industry; Surgery, including the implantation procedure; Integrated circuit manufacturing; Isolation and treatment

Cleanliness standard requirements for clean room

Friday, 28 May 2021

In order to meet the cleanliness requirements of the clean room, there are four requirements need to meet. ● Air supply cleanliness The key to ensure the cleanliness of the air supply is the performance and installation of the final filter of the clean room system. ● Air flow organization The airflow organization of the

Construction scheme for a modular standard clean room project

Saturday, 10 April 2021

Construction conditions Clean rooms are not allowed to use wood materials and other materials that do not meet the requirements of cleanliness standards. All kinds of materials should be stored in a clean and dry environment with enclosure. The thickness, specification, size specification and quality of the sandwich panel must conform to the design requirements